ISO 9001

Quality Management

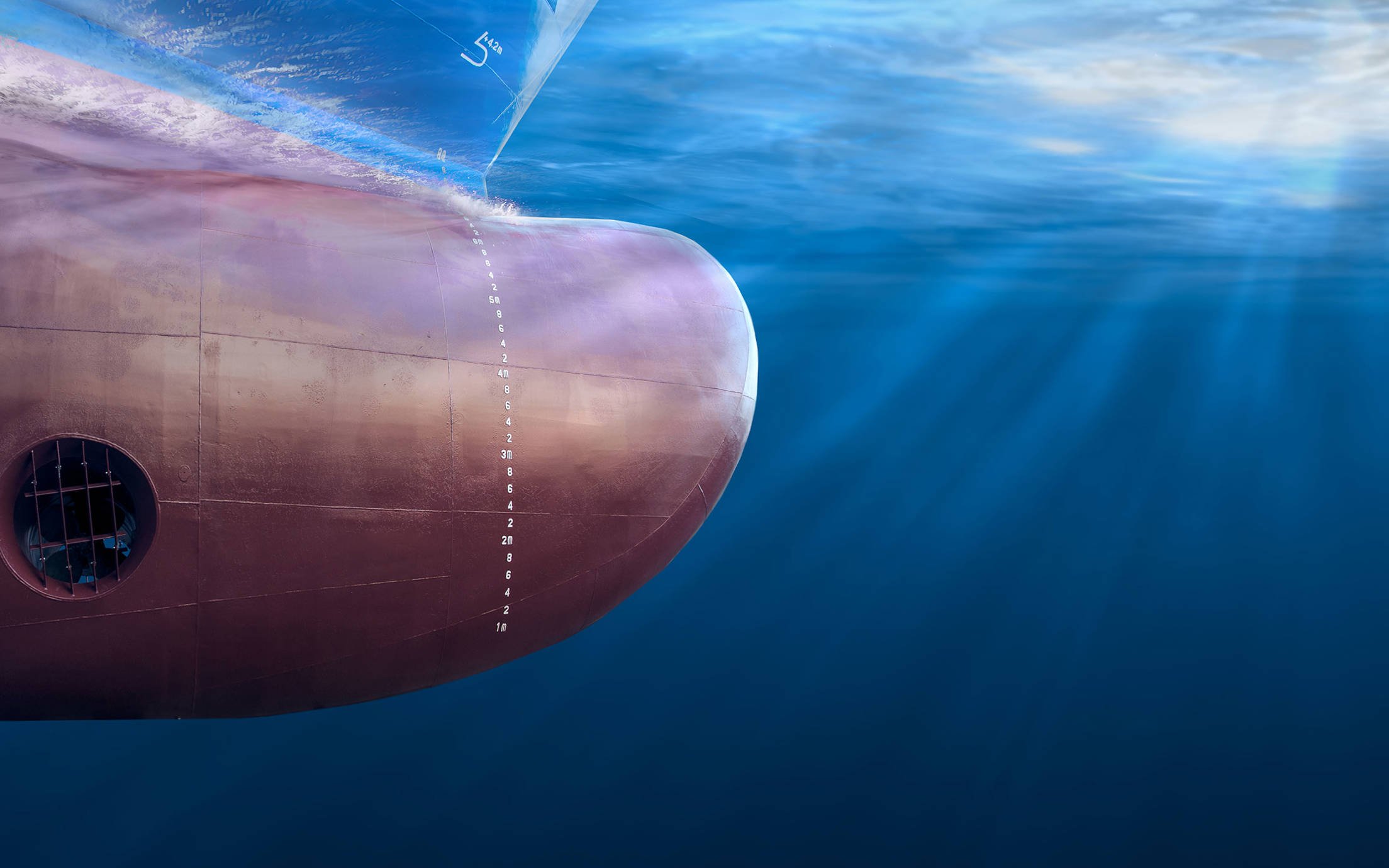

Fast-moving industrial environments like ours pose risks to people, property, and the world around us.

Our response to these risks goes further than simply complying with safety regulations and following procedures in the hope of managing avoidable risk.

We recognise that creating risk awareness and optimising processes is effective in driving better safety standards. But we believe that for long-term, sustainable results, our focus needs to be on eradicating risk altogether.

That's why the main principle of our HSEQ strategy is to continuously improve safety and quality performance across the company value chain, with a zero-tolerance approach to injuries, fires and spills.

In addition, we have an ongoing initiative called "I Care", through which we ensure that employees demonstrate their individual ownership of and commitment to HSEQ.

In our drive to continuously and proactively identify and neutralise potential threats to employee and environmental safety, and maintain optimal manufacturing performance, we:

Every incident or potential incident reminds us that the push for zero is our top priority.

The Jotun HSEQ Management System outlines the rules and regulations that must be implemented across the company. Specifically, it provides the structure to track and manage 15 factors related to health, safety, environment, and product quality management.

We expand and update the system regularly, and a great example is "Safety in Projects," which we added in 2019 to ensure a uniform approach to the risks associated with construction projects.

To ensure every corner of Jotun's global manufacturing and supplier network aligns with corporate goals, every subsidiary and supplier must delegate HSEQ responsibilities to key individuals for local implementation.

We perform audits every three years to verify compliance with HSEQ procedures.

Quality Management

Environmental Management

Occupational Health and Safety

Our pledge to ensure workplace safety is unshakeable. In line with our commitment to conducting business in a responsible manner, we also work continuously to conserve energy, reduce waste and the use of harmful chemicals, and slash our carbon footprint.

We measure and record key indicators on an ongoing basis to track our progress. The graphics below demonstrate continuous improvement in four areas:

Every Jotun employee can contribute personally and directly to making their workplace safer through the ongoing I Care initiative.

We run three separate I Care projects every year. Group head office initiates one and rolls it out worldwide, and each of the manufacturing sites companywide launches the other two.

The choice of theme is based on needs and risk factors identified within Jotun production units and varies annually. Typical themes include fire and man-machine safety with a focus on critical installations and employee behaviors.

Our goal is to motivate Jotun employees to identify risks and then implement risk-reducing initiatives in their own operations. The outcomes from I Care campaigns are carefully measured, and improvements are rewarded both individually and at a team level.

The real and positive impact of I Care on our HSEQ performance is exemplified in the graph above which shows the steady reduction in the lost time injury rate between 2015 and 2020.

A video is being shown

An image is being displayed

A brochure is being displayed