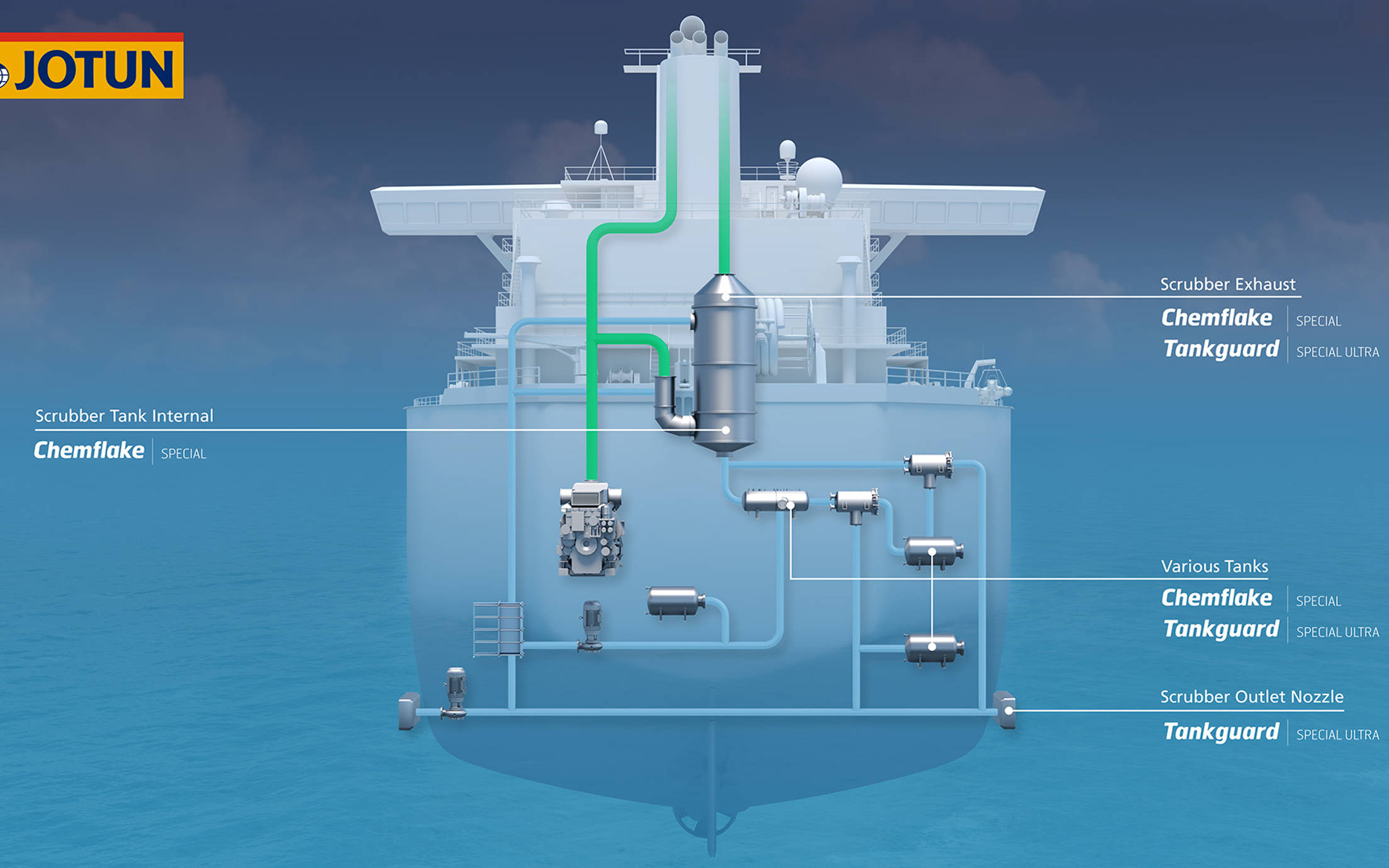

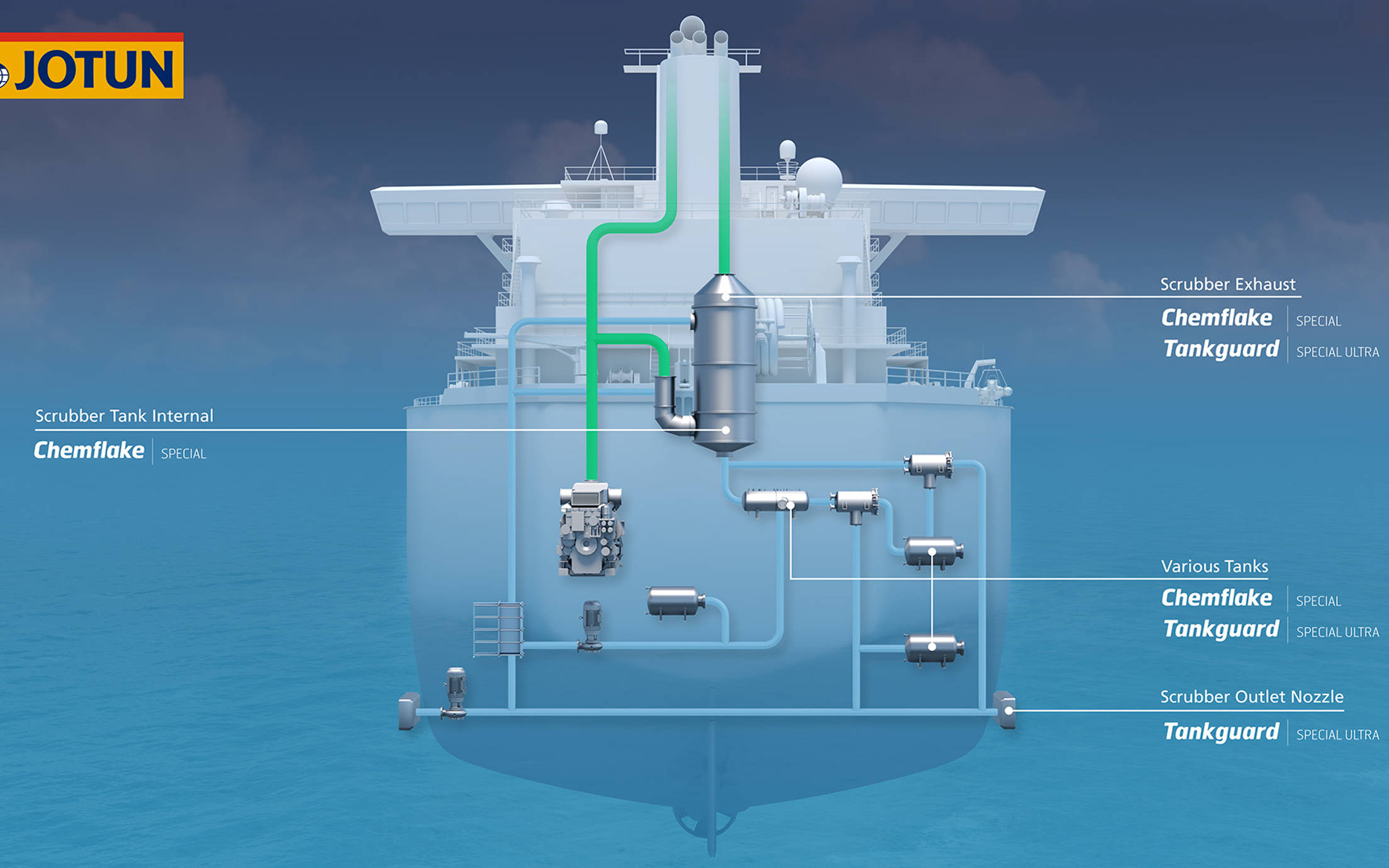

Focus on scrubber-proof coatings

Scrubber systems can play an important role in compliance with upcoming IMO 2020 regulation. However, one often overlooked aspect of installation is paint selection.

The economical and environmental impact of fouling, combined with increasing legislation, are adding to the pressure for more innovation and improvement in hull cleaning methods.

Fouling is a pressing issue in shipping as it increases the ship’s drag through water and adds to the fuel used, which impacts on the ship’s greenhouse gas emissions and commercial performance. According to the International Maritime Organisation (IMO), poor hull and propeller performance is currently estimated to account for around 10% of the world’s fleet energy consumption and corresponding greenhouse gas emissions.

Preventing fouling can be done in a variety of ways and there are specialist products developed by coating makers to suit a wide range of vessel types and operating parameters. Assuming a ship’s antifouling coating has been applied correctly, the coating should remain effective in preventing fouling for its intended lifetime. Problems arise, however, when the coating has been damaged in some way, or has not been properly matched to its operating profile and drydocking schedule.

Indeed, many vessels spend time in challenging environments or are deployed in difficult operational profiles. This may mean that the operation experiences long idle periods, low average speed, frequent port calls or trade in areas with high fouling risk. Such circumstances can prove challenging from a hull performance point of view and require proper attention since the current solutions on the market struggle to address these problems. Also, operational profile factors outside coating tolerance such as speed, activity and temperature can be encountered for a variety of reasons.

Aside from cleaning or replacing the antifouling during drydockings, hulls and propellers may be cleaned occasionally in water while in service. Historically, this would have been done only if it was evident there was heavy fouling. Today, performance monitoring software tools make it possible to detect varying degrees of fouling based upon the ship’s performance data and allow for cleaning to be arranged before more fouling turn the situation into a major problem.

Traditionally cleaning would be done by teams of divers and this is still a method that is in common use, however, there are existing issues. As pointed out by Dr Mario Tamburri, Director of Alliance for Coastal Technologies (ACT) and Marine Environmental Resource Center (MERC), in-water cleaning with divers/or scrubbing machinery can be effective in removing biofouling, but it has its drawbacks. These may include damage to the shipowner’s expensive anti-fouling coating (leading to increased fouling risks), the release of potentially harmful biocides from coatings, health and safety issues with diver teams, and, crucially, the release of macrofouling and coating biocides into the local waters where cleaning takes place.

Consequently, cleaning by divers is not permitted in many ports and because of the threat of invasive species, authorities in New Zealand, Australia, California and the EU have already introduced new requirements on owners. Several more are threatening controls or complete bans.

A growing number of industry stakeholders believe it is only a matter of time before the IMO will regulate biofouling. It took another step towards biofouling controls when it led the establishment of the GloFouling Partnerhips project last year. Backed by major industry stakeholders, the aim of the project is to drive actions to implement the IMO Guidelines for the control and management of ships’ biofouling to minimise the transfer of invasive aquatic species (IMO Biofouling Guidelines).

Another way to clean hulls is with one of the various specialist hull cleaning devices that several contractors are now utilising. These vary from hand-held models that divers can use to ROVs (remote operating vehicles) operated either by a diver or, if they are fitted with cameras, from onshore by a trained operator. While not yet commercialised, there is also discussion of robot devices that can be kept onboard and used regularly to remote light fouling.

The devices currently in use globally vary from types that use brushes to remove the fouling and those that use high pressure water jets to dislodge organisms and weed growth without coming into contact with the coating itself. The devices that make use of brushes may come with a choice of cleaning heads allowing one best suited to the type of coating and type of fouling observed to be used. To overcome the environmental impact of dislodged fouling being released, many of the machines also have a collecting facility so that the removed growth and organisms can be safely disposed of in a controlled manner.

The main benefits of using cleaning devices is that they are faster and more effective than divers. However, the use of robot devices have traditionally been very costly and required extensive training to operate. Also, the current solutions on the market do not offer the operational flexibility of ‘anywhere, anytime’ cleaning and inspections.

As companies are getting more inventive and coming up with new technologies and solutions, more ship owners are calling for the development of best practices and standards for improved in-water cleaning. For this reason, BIMCO, the largest maritime trade group in the world, is developing an internationally recognised standard on in-water hull and propeller cleaning that will ensure good quality cleaning fulfilling a set of specifications.

Speaking in connection with BIMCO’s recent biofouling webinar, Ashok Srinivasan, manager of marine technology & regulation at BIMCO said, “There is a definite need for an in-water cleaning standard because the results of cleanings vary, and the quality needs to be improved. Also, the safety, environmental impact and coating impairment must be controlled. There is also a lack of available cleaning facilities, and alternatives like dry-docking are expensive and cumbersome.”

The standard is being developed with a group of industry partners and is expected to be published shortly. BIMCO has also submitted the results of its recent biofouling survey to the IMO to contribute with insight into biofouling practices ahead of the IMO’s revision of its existing biofouling guidelines next month.

As biofouling continues to attract an increasing amount of attention from states, regulators, owners, and port authorities around the world, it is likely that the forward-thinking companies and organisations will take a proactive role in developing solutions and shaping next generation hull maintenance and performance management.

**

According to the International Maritime Organisation (IMO), poor hull and propeller performance is currently estimated to account for around 10% of the world’s fleet energy costs and corresponding greenhouse gas emissions. This translates to about USD 30 billion in additional fuel costs for the world fleet, every year. Fouling also contributes to the transfer of invasive aquatic species between different environments.

Scrubber systems can play an important role in compliance with upcoming IMO 2020 regulation. However, one often overlooked aspect of installation is paint selection.

High profile speakers and shipping executives at Nor-Shipping stress importance of innovation and collaboration amid changing landscape and tightening environmental regulations.

Norway is well-positioned to lead efforts for the transition to low-carbon shipping, but government and shipping executives stress more collaboration, technology and innovation is needed to achieve global emission reduction goals.

A video is being shown

An image is being displayed

A brochure is being displayed