Great minds for groundbreaking solutions

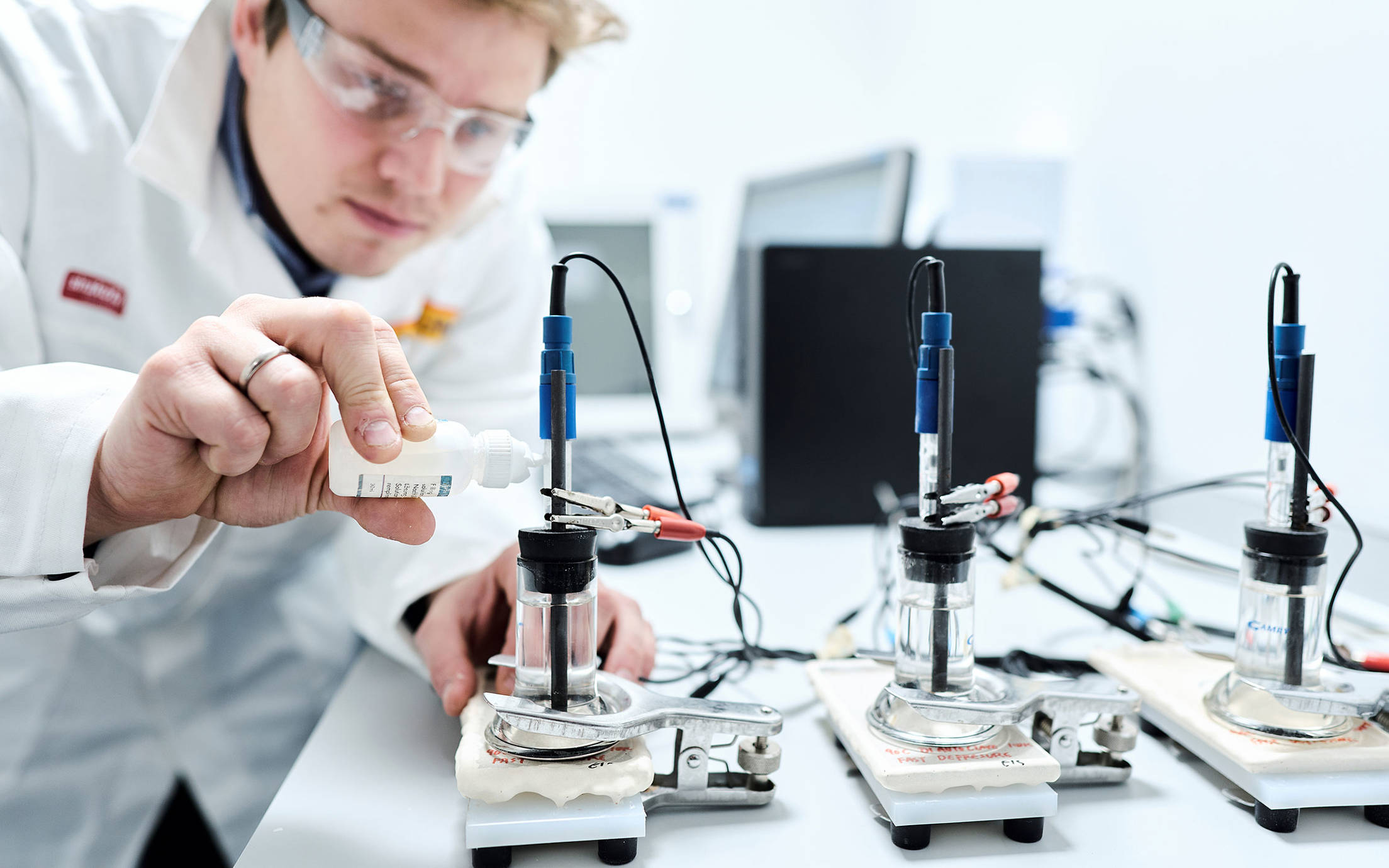

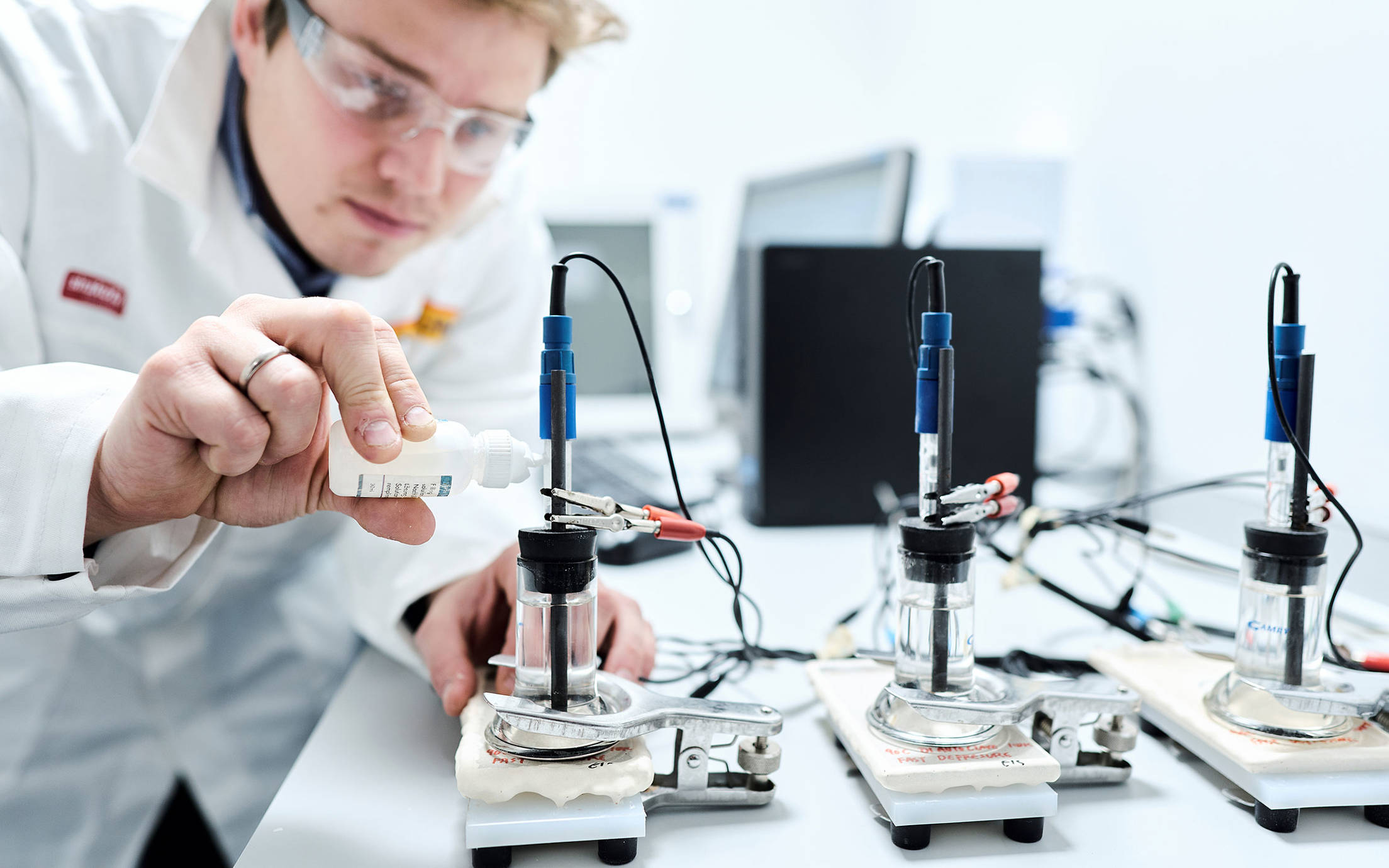

Working in Jotun R&D is much more than white lab coats and protective glasses. Prepare to get your hands dirty and learn about a global growth company with vast career possibilities.

Jotun has been waging an ongoing battle against the elements for almost a century. We develop products that can perform under a wide range of conditions and meet the customer's specifications and expectations.

In every corner of the world, our premium paints and coatings stand as the last line of defense against weather and wind, as well as biofouling, hydrocarbon fires and year-round precipitation.

To ensure our products are up to the task, we constantly test them under the harshest conditions imaginable. Using a combination of field testing and the technology available at our modern R&D facilities, we are able to document and prove the performance of our coating solutions.

The paint and coating industry has developed massively in this respect. Today, customers, partners and regulators alike all demand in-depth analysis, documentation and data. This is why we need to know – and be able to document – that our products perform as expected under in-service conditions.

In order to achieve this, we use our state-of-the-art laboratories. In our R&D facilities, we simulate every imaginable temperature and weather scenario, in addition to other environmental conditions that might affect and damage ships, houses and other structures.

Accelerated laboratory testing should always be verified and supplemented by field testing. Therefore, Jotun has test stations in places such as Svalbard, known for one of the coldest and most unstable climates on the planet. We perform tests at our site close to the Norwegian research station Troll in Antarctica, with extreme UV radiation and lots of wind. We also test our products in the hottest and most humid and corrosive environments on Earth – such as South East Asia and The Middle East.

Properly assessing the protective properties of the coatings requires both natural and accelerated tests. For example, accelerated corrosion tests expose the panels to severely corrosive environments such as seawater to determine the ability to limit the corrosive damage.

Of course, harsh weather is not the only threat to the durability of our paints and coatings. That’s why we also subject them to a wide range of mechanical tests to assess the hardness, durability, and resistance to threats such as impact, abrasion, and scratches.

For our decorative product line, we conduct regular painting workshops where we collaborate with professional painters who provide us with vital feedback, both in trials and blind tests.

In addition to our internal extensive and rigorous testing, we have external third-party institutions approving and certifying our coating solutions according to internationally accepted standards and specifications. This builds trust and confidence in the performance of our coating systems and ensures that we meet governmental legislation, authorities’ requirements and customer demands.

All this required testing demands substantial resources. However, we need to see the full picture of a coating systems performance to ensure that we provide the best possible protective solution for our customer’s assets because “Jotun protects property”.

Working in Jotun R&D is much more than white lab coats and protective glasses. Prepare to get your hands dirty and learn about a global growth company with vast career possibilities.

Our team of expert scientists focus on addressing global challenges, as well as adapting to local specifications and requirements throughout the world.

To share and develop knowledge, understanding and technology – as well as enable world leading and sustainable products and solutions – we join forces with academia and external partners.

A video is being shown

An image is being displayed

A brochure is being displayed